The brush is a traditional Chinese writing and painting tool.

Huang Tingjian of the Song Dynasty believed that among the four treasures of the study, the most difficult one was the production of brushes. A purely handmade brush goes through more than a dozen processes from material selection to completion.

As the saying goes: “The hair of a brush cannot even be touched by gods.” The difficulty in making a brush lies in how to make it “pointy, even, round, and healthy.”

It is very difficult to control the sharpness, bluntness and fatness of a brush. A brush generally needs to go through about a dozen major processes such as material selection, water basin, knotting, casing, pouf, inlay, brush selection, and engraving .

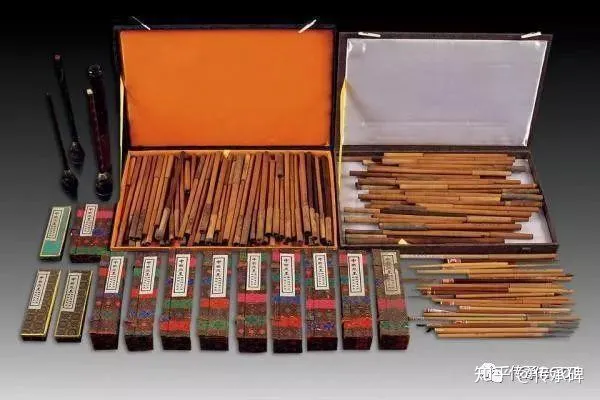

The most famous brushes include Hu brushes from Huzhou, Zhejiang, Taicang brushes from Henan, Houdian brushes from Hebei, Changkang brushes from Xiangyin, Hunan and Wengang brushes from Jiangxi.

Writing brushes are made of animal hair, which can be divided into hard hair, mixed hair, and soft hair. Common materials for making brushes include weasel hair, goat hair, rabbit hair, raccoon hair, etc., horse hair, chicken hair, dog hair, etc.

How is the tip of a brush made? Let’s look at the steps –

- Selection of wool materials, fine grain selection

The material of the brush tip is very particular. The fine hairs of animals are affected by factors such as species, sex, hunting season, etc. The length and quality of the brush tip have a great influence on the brush tip.

The wool material determines the purpose of various pens. The soft-hair series is mainly made of wool , while the hard-hair series uses wolf hair, horse hair, pig bristles , etc. In addition to the type of hair, the length, thickness, growth and season of use of the hair are also important factors in making a pen. The key factors to holding a good brush.

When starting to make it, you need to tear the animal hair apart and retting it with quicklime for about a week to remove the fishy smell. You can take it out when the pile of hair looks black.

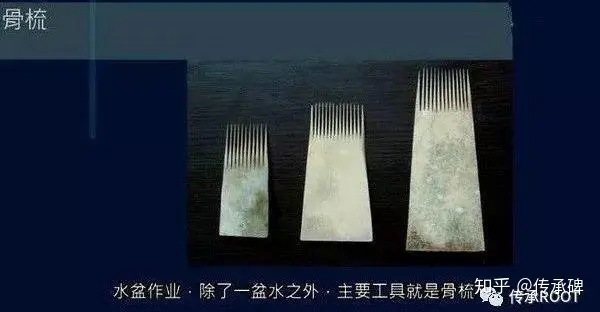

- Comb the hair and remove the fluff

After the wool is gathered together, use a bone comb to comb out the fluff. Because the fluff is thin and curved, it cannot become wool. If the fluff is not removed, it will easily cause the brush to split.

Combing wool “needs to be combed hundreds of times, and the wool is constantly dipped in water during the combing process. Blacksmiths are called to seek wealth from the fire, but what we do in this industry is to seek wealth from the water.”

Add water to comb and degrease

“History of Brushwork” says: “The most difficult thing about brushwork is choosing the hair.”

Since the millimeter material has differences in oblateness, curvature, length, thickness, etc., it is necessary to repeatedly clean the degreased millimeter material in a water basin with a horn comb (mostly a comb made of ox horn) for further sorting.

The fine picking work in the water basin process requires extremely fine work, requiring selection, classification and combination one by one. Made into blade-like “blade hair”. Then the bad hair is removed, “even hair” is carried out, and it is shaped into a pen tip.

The water basin process is divided into sheep water basin, double water basin, etc. according to different materials.

- Arrange Mao Feng

Each piece of wool is different in length. In order to make it uniform, the piles of hair after depilation are arranged one by one on the board in the direction of the hair tip, and then the hair roots are cut evenly, which is the “hair piece” in the wool.

- Prepare wool according to proportion

A pen is rarely made of a single type of wool; most of it is a mixture of two or three or more types of wool. To get it just right requires a lot of experience, so the blending of wool is done personally by master craftsmen.

- Cut the pen shape

The thickness, thickness, length of the tip of the pen, as well as the smoothness of the pen shape, deeply affect the pen quality. Therefore, the prepared wool materials need to be cut into shapes separately to meet the needs of the pen tip. Therefore, the cutter is used to make pens. The key to success or failure.

After cutting, the wool needs to be combed and smoothed again. Use an ox bone comb to comb the wool from the root to the tip of the brush. After combing it neatly, repeat the combing several times until the entire wool is evenly mixed.

Finally, the pen maker has to pick out miscellaneous hairs, coarse hairs, and broken hairs from the combed wool to make it more perfect and neat.

- Combing and mixing

Mix and comb the well-cut wool materials several times with a bone comb to make the various wool materials evenly distributed. In this way, the shape of the finished pen will not be skewed when writing.

- Rolled pen core

Comb the mixed hair pieces, take a part and smooth it, then roll it on the palm of your hand to make a pen core, and then spring the pen root to make the hair roots flat. If there are unflattened hairs, use a foreskin knife to remove them.

- Wrapped skin

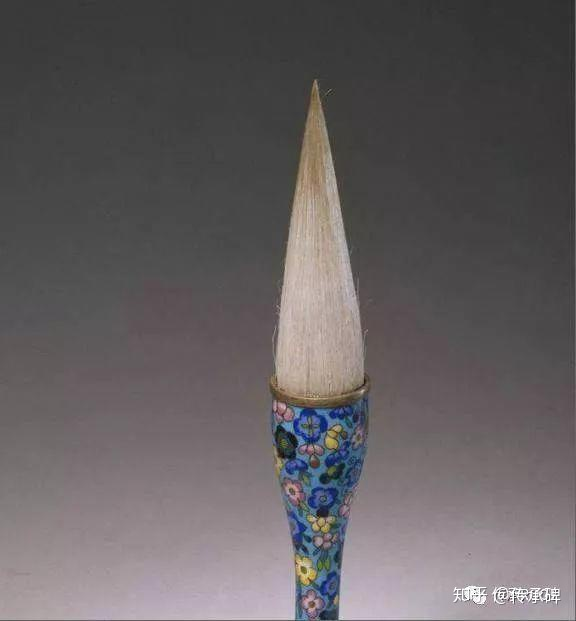

The outer layer of the brush hair is also called the foreskin. After the stamen is formed, the foreskin is covered by rolling the stamen. Then the tip of the pen is adjusted and the broken edge of the hair tip is removed. Only here can the writing be smooth.

- Knotting process

The knot is the tip of the ligation pen, also called “tie hao”. “History of the Pen” says: “It is important to tie the pen tightly. If a hair comes out, it will become unusable.”

After the wool is processed, it is divided into bundles, dried, and tied up. This is the pen tip (the pen tip must be dried before it can be tied up, otherwise it will not be strong and easy to shed hair).

Hang the made pen head up for three days. During the hanging process, the wool will become tighter and tighter. When you take it off after three days, you can’t pull it out even if you try hard by hand.

- Make a brush holder and choose a tube

Select the wild bamboo from the local mountains and forests, grind, cut, and drill holes before use. Pipe selection has certain requirements for pipe diameter, pipe length, roundness, and straightness, and pipe materials that are dry, insect-eaten, withered skin, and uneven in thickness must be removed.

According to the different types of bamboo, pen makers divide pen holders into white bamboo tubes, square bamboo tubes, purple bamboo tubes, brown bamboo tubes, Xiangfei bamboo tubes, etc. The textures and colors of these pen holders are different, and the pen makers will customize them according to the customer’s requirements. Choose the most suitable bamboo for the pen holder according to your needs and the matching of the pen head.

The pen holder is made of many materials, such as bamboo, wood, jade, porcelain, ivory, horn, plastic…

- Set up

Put the prepared brush tip into the bamboo pen holder.

First, file both ends of the pen barrel flat, and then cut one end into a cavity. The hole size must be suitable for the thickness of the pen tip to fit the pen tip. The assembly work also includes fitting the pen cap.

- Adhesive pen tip

To stick the pen tip to the pen holder, rosin glue was used as the main adhesive in the early days. Nowadays, strong glue commonly known as “iron glue” is mostly used.

After the brush is made, the brush maker must first use the test tip. During the trial, the brush dipped in clean water is used to write in various directions to test whether the brush tip can rotate freely.

If any stray hairs or impurities are found during the trial, the bristles need to be readjusted, glued again, and repeated several times to make a brush.

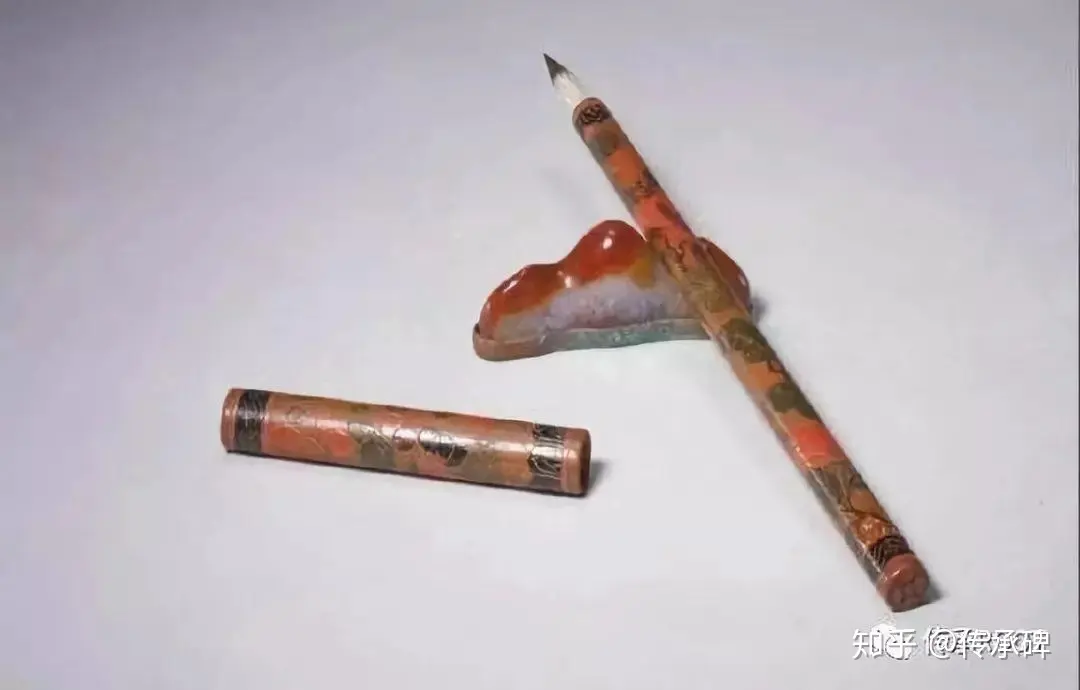

Thirteen, inlay

The inlay process is to use decorative items (such as horns, etc.) to process and decorate the pen barrel to make it beautiful.

Inlaying is divided into inlaying head and inlaying tail. Inlaying head is also called mounting bucket, and inlaying tail is also called hanging head. The process requires even mouth and surface, smooth starting line, tight connection, clear threads, etc.

Inlaid with ivory front and back

The pen barrel has been inlaid and processed to make it appear exquisite and gorgeous, or simple and elegant, making it both excellent in appreciation and good in use.

- Set the bristles into shape and apply them as desired

Selective wiping is to twist the pen hair into the shape of the pen tip, remove the curved vellus hair, and smooth the pen tip.

After the pen tip is selected and applied, it can have the properties of sharp, straight, round and strong, and the appearance will also be sharp and delicate, and the shape will be beautiful.

A good writing brush should have the characteristics of “point, neatness, roundness and health”. “Jian” means the tip of the pen is sharp; “Qi” means it is trimmed neatly; “Yuan” means the tip of the pen is round; “Jian” means the brush has strong elasticity and the written words are sharp and vigorous

- Pen holder engraving

The engraving process is the process of engraving pen names, trademarks, inscriptions, etc. on the pen barrel. It is required to have a suitable layout and even arrangement based on the number of words and font style.

The engraved pen barrel has a “relief” artistic effect, coupled with inlaid decoration and painted brocade, it makes the pen pleasing to the eye.

An excellent calligrapher must not only have superb pen-making skills, but also have a deep understanding of the essence of calligraphy, and must not be greedy for money and profit. Otherwise, it will be difficult to reach the state of “techniques can advance to the Tao, and arts can reach the gods.”

At present, the production of calligraphy brushes is in the same situation as other traditional handicrafts. It also encounters a crisis of skill inheritance and there are few successors. There are less than 1,000 people working in the field of writing, only a few thousand in Huzhou, and more than 10,000 in Jiangxi.

Not only does it take a long time to make a brush, from raw materials to finished product, it takes at least 45-50 days, but it also involves more than 120 processes. No matter how sophisticated the machine is, it cannot replace manual work.

The inheritance of brush skills has become a problem now. “If you are not famous, how much money can you make by making a brush? And because it is purely handmade, it is considered good if you can make 100 brush heads in a day.” The brush craftsman told reporters , making brushes by hand is time-consuming and labor-intensive, and the economic benefits are not ideal, which makes many people unwilling to learn this skill.

Find the most valuable inheritance in the longitude and latitude of time and space!

For more inheritance articles about people and things, please follow our WeChat public account “Inheritance ROOT”!

Video introduction to making brushes